Annealing is a process by which steel is reheated to alter its mechanical properties and microstructure, making it more suitable for various applications. This technique involves heating the steel to a specific temperature, holding it at that temperature for a predetermined time, and then cooling it at a controlled rate.

By manipulating these parameters, manufacturers can achieve desired outcomes in terms of hardness, strength, ductility, and toughness.

Annealing plays a crucial role in the steel industry, enhancing the performance and versatility of steel products. It finds applications in sectors such as automotive, construction, and manufacturing. Understanding the annealing process and its effects on steel is essential for engineers, metallurgists, and anyone involved in steel production and utilization.

Annealing Process Overview

Annealing is a crucial process in steel production that involves controlled heating and cooling to alter its properties. The primary objectives of annealing include:

- Softening the steel, making it more ductile and easier to work with

- Relieving internal stresses and preventing cracking during subsequent processing

- Improving machinability and surface quality

There are different types of annealing processes, each tailored to specific steel grades and desired outcomes. These include:

- Full Annealing: Heating the steel to above its critical temperature, holding it there, and slowly cooling it to room temperature.

- Process Annealing: Heating the steel to a temperature below its critical temperature, holding it there, and cooling it at a controlled rate.

- Stress Relief Annealing: Heating the steel to a temperature below its critical temperature, holding it there, and slowly cooling it to room temperature.

Annealing Procedure

The annealing procedure involves several key steps:

- Heating:The steel is heated to the desired temperature, typically above its critical temperature for full annealing or below it for process or stress relief annealing.

- Holding:The steel is held at the target temperature for a specific duration to ensure uniform heating and allow for microstructural changes.

- Cooling:The steel is cooled at a controlled rate, which significantly impacts the final properties of the material.

The temperature ranges, holding times, and cooling rates vary depending on the type of annealing process and the desired results.

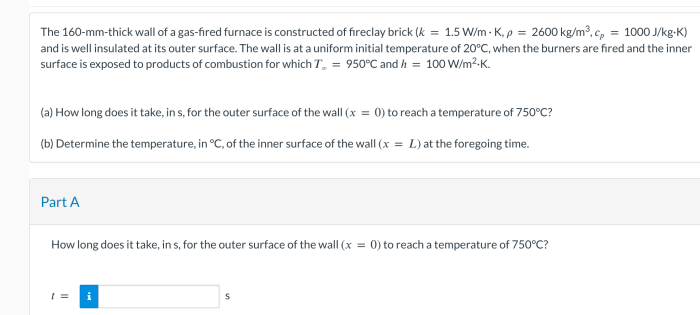

Annealing Equipment and Instrumentation

Annealing processes utilize various equipment and instrumentation to achieve precise control and monitoring:

- Furnaces:Heating chambers used to heat the steel to the desired temperature.

- Thermocouples:Sensors that measure and monitor the temperature of the steel during heating and cooling.

- Temperature Controllers:Devices that regulate the temperature inside the furnace based on the desired annealing parameters.

- Cooling Systems:Mechanisms for controlling the cooling rate, such as fans, water jets, or controlled gas flow.

Advancements in annealing technology have introduced automated systems and advanced instrumentation for precise temperature control, monitoring, and data logging.

Effects of Annealing on Steel Properties

Annealing significantly influences the mechanical properties of steel:

- Hardness:Annealing softens the steel by reducing the amount of carbon dissolved in the iron lattice.

- Strength:Annealing decreases the strength of steel, as the softer material is less resistant to deformation.

- Ductility:Annealing improves ductility, making the steel more pliable and able to deform without breaking.

- Toughness:Annealing increases toughness, enhancing the steel’s ability to absorb energy before fracturing.

These property changes influence the suitability of steel for various applications, such as formability, machinability, and structural integrity.

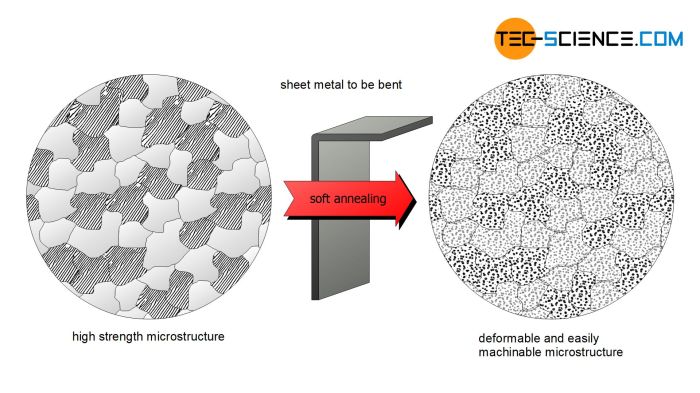

Microstructural Changes during Annealing

Annealing induces microstructural changes in steel:

- Phase Transformations:Annealing allows for the formation of desired phases, such as ferrite and pearlite, by controlling the heating and cooling rates.

- Grain Growth:Annealing at higher temperatures can promote grain growth, affecting the material’s strength and toughness.

- Precipitation:Annealing can facilitate the precipitation of carbides or other particles, influencing the steel’s hardness and wear resistance.

Understanding these microstructural changes is crucial for optimizing the annealing process and achieving the desired material properties.

Applications of Annealing in Steel Industry: Annealing Is A Process By Which Steel Is Reheated

Annealing is widely used in the steel industry for various applications:

- Wire Drawing:Annealing softens the steel, making it easier to draw into wires for electrical or mechanical applications.

- Cold Rolling:Annealing prepares the steel for cold rolling, improving its ductility and preventing cracking.

- Machining:Annealing enhances machinability, making the steel easier to cut and shape.

- Stamping:Annealing softens the steel, allowing for complex stamping operations without cracking.

- Welding:Annealing can relieve stresses and improve weldability.

Annealing plays a vital role in enhancing the performance and suitability of steel products in various industries.

Safety Considerations in Annealing Processes

Annealing processes involve potential hazards that require safety precautions:

- Extreme Temperatures:Furnaces operate at high temperatures, posing risks of burns or fire.

- Toxic Fumes:Annealing can release toxic fumes, such as carbon monoxide, requiring proper ventilation.

- Mechanical Hazards:Moving parts of annealing equipment can cause injuries.

Industry standards and regulations, such as OSHA guidelines, provide safety measures and protocols to minimize risks associated with annealing processes.

Popular Questions

What is the purpose of annealing steel?

Annealing is used to soften steel, relieve internal stresses, refine the grain structure, and improve its machinability and formability.

How does annealing affect the hardness of steel?

Annealing generally decreases the hardness of steel by softening the material and reducing its yield strength.

What are the different types of annealing processes?

Common annealing processes include full annealing, process annealing, stress relief annealing, and spheroidizing annealing.

What is the role of temperature in annealing?

Temperature plays a critical role in determining the extent of microstructural changes and the resulting properties of the annealed steel.

How is the cooling rate controlled during annealing?

Cooling rate is controlled by adjusting the cooling medium and its temperature. Slower cooling rates promote the formation of larger grains, while faster cooling rates result in finer grains.