The mower exerts a force, a fundamental concept that governs the operation and effectiveness of this essential lawn care tool. Delve into this article to unravel the intricacies of force as it relates to mowers, exploring the types of forces involved, the factors that influence their magnitude, and the practical applications of force analysis in optimizing mower performance and safety.

From understanding the principles of force measurement to identifying strategies for maximizing efficiency, this comprehensive guide provides a thorough examination of the mower’s force exertion, empowering readers with valuable insights and practical knowledge.

Force Exerted by the Mower: The Mower Exerts A Force

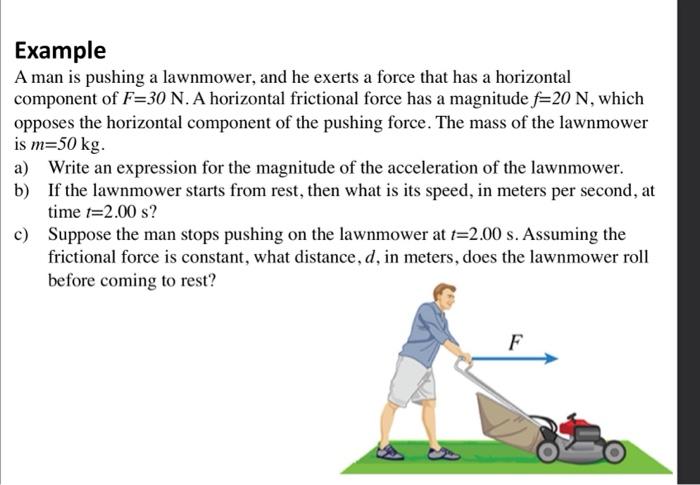

Force is a fundamental concept in physics that describes an interaction capable of changing the motion of an object. In the context of a mower, force plays a crucial role in its operation and effectiveness.

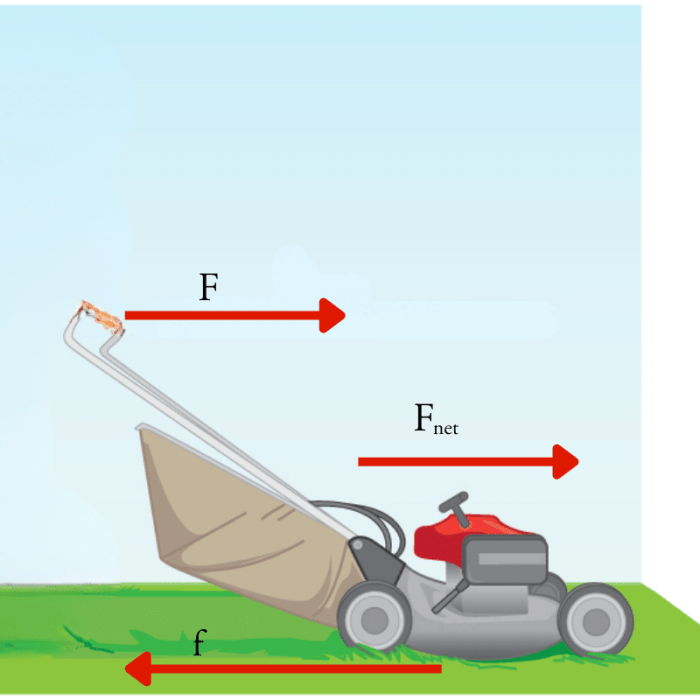

The mower exerts several types of forces, each contributing to its function:

Cutting Force, The mower exerts a force

The primary force exerted by the mower is the cutting force. This force is applied to the grass blades, causing them to be severed. The cutting force is generated by the rotating blades of the mower, which are powered by the engine or motor.

Pushing/Pulling Force

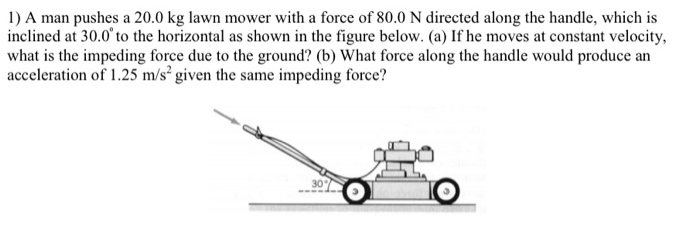

The mower also exerts a pushing or pulling force, depending on its design. This force is used to propel the mower forward or backward, allowing the operator to control its movement. The pushing/pulling force is generated by the wheels or tracks of the mower.

Traction Force

The mower exerts a traction force to overcome the resistance of the ground and maintain contact with the surface. This force is generated by the tires or tracks of the mower, which provide grip and prevent slippage.

Centrifugal Force

As the mower’s blades rotate, they create a centrifugal force that helps to eject the cut grass from the mower deck. This force ensures that the cut grass is dispersed evenly and does not clog the mower.

Factors Affecting the Force

The force exerted by a mower is influenced by several key factors. Understanding these factors is crucial for optimizing mowing efficiency and minimizing strain on the operator.

Mower Type

The design and type of mower significantly impact the force required to operate it. Rotary mowers, with their spinning blades, require less force compared to reel mowers, which cut grass with scissor-like action. Self-propelled mowers reduce the effort required by the operator, while manual push mowers necessitate greater force.

Grass Height and Density

The height and density of the grass affect the resistance encountered by the mower blades. Taller grass and denser growth require more force to cut through, as the blades must overcome increased resistance. In contrast, shorter grass and sparse growth offer less resistance, reducing the force required.

The mower exerts a force on the grass, pushing it down and cutting it. For those struggling with math problems, there’s a helpful resource available online: math for apes answer key . Returning to the mower, the force it exerts is proportional to the area of the grass it cuts.

Terrain Slope

The slope of the terrain plays a role in determining the force exerted by the mower. Mowing on a slope requires additional force due to the resistance of the mower against gravity. Uphill slopes demand more force, while downhill slopes reduce the force needed.

Blade Sharpness

Sharp mower blades significantly reduce the force required to cut grass. Dull blades increase resistance, requiring more force to achieve the same cutting results. Regular blade sharpening ensures optimal performance and reduces strain on the operator.

Measurement and Calculation of Force

Measuring the force exerted by a mower is crucial for evaluating its performance and efficiency. Several methods and techniques are employed to determine this force accurately.

One common method involves the use of a force gauge. This device is placed between the mower and the surface being cut, allowing it to measure the force applied during the mowing process. The gauge typically displays the force reading in units of newtons (N) or pounds-force (lbf).

Principles of Force Measurement

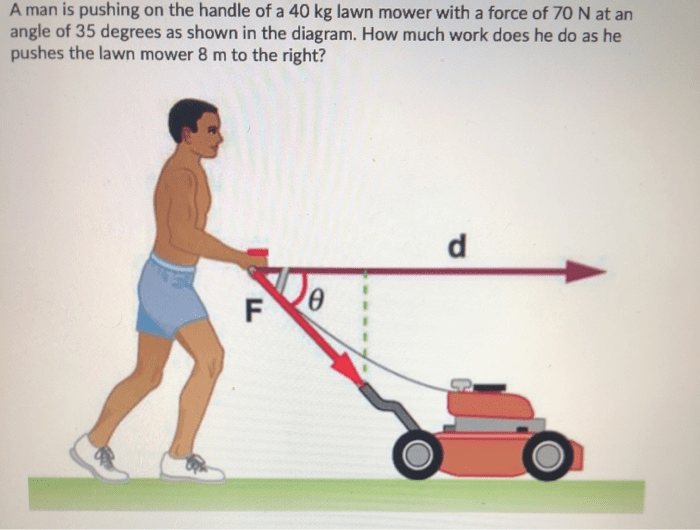

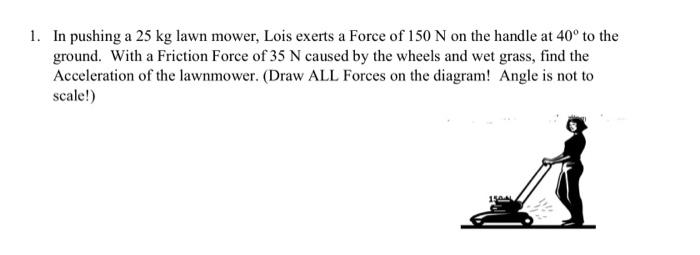

Force measurement relies on the principles of Newton’s laws of motion. Newton’s second law states that the force acting on an object is directly proportional to the mass of the object and its acceleration. In the case of a mower, the force exerted is proportional to the resistance encountered while cutting the grass, which depends on factors such as grass height, density, and moisture content.

Step-by-Step Calculation of Force

To calculate the force exerted by the mower, follow these steps:

- Measure the force using a force gauge or other appropriate method.

- Determine the mass of the mower, which can be found in the manufacturer’s specifications.

- Calculate the acceleration of the mower, which can be estimated based on the speed of the mower and the distance traveled over a given time.

- Apply Newton’s second law (F = ma) to calculate the force exerted by the mower.

F = ma

where:* F is the force exerted by the mower (N or lbf)

- m is the mass of the mower (kg or lbm)

- a is the acceleration of the mower (m/s² or ft/s²)

Applications of Force Analysis

Analyzing the force exerted by a mower has significant practical applications in various industries and scenarios. Understanding these forces enables engineers and manufacturers to design mowers that are efficient, safe, and meet specific performance requirements.

Design and Optimization

- Force analysis helps determine the optimal blade design, including the shape, size, and material used. By optimizing the blade’s geometry and material properties, engineers can enhance the mower’s cutting efficiency and reduce wear and tear.

- It also assists in designing the mower’s drive system to ensure it can generate sufficient force to cut through different types of vegetation without stalling or overheating.

Safety Enhancements

- Force analysis is crucial for ensuring the safety of mower operators. By understanding the forces involved, engineers can design mowers with ergonomic handles and vibration-dampening systems to reduce operator fatigue and the risk of injuries.

- It also helps determine the appropriate safety mechanisms, such as blade guards and rollover protection systems, to minimize the risk of accidents and protect operators in case of unforeseen events.

Performance Evaluation

- Force analysis provides valuable insights into the mower’s performance under different operating conditions. By measuring the force exerted by the mower, engineers can evaluate its cutting efficiency, power consumption, and overall performance.

- This information can be used to compare different mower designs, optimize operating parameters, and identify areas for improvement.

Maintenance and Troubleshooting

- Understanding the forces involved in mower operation helps identify potential maintenance issues and develop preventive maintenance strategies.

- By monitoring the force exerted by the mower over time, technicians can detect changes that may indicate worn components or potential problems, allowing for timely repairs and maintenance to ensure optimal performance and extend the mower’s lifespan.

Optimization of Force Exertion

Optimizing the force exerted by a mower is crucial for enhancing efficiency, minimizing energy consumption, and ensuring optimal performance. By implementing specific techniques and strategies, users can maximize the mower’s effectiveness and reduce the physical effort required.

Techniques to Optimize Force Exertion

- Sharp Blades:Maintaining sharp mower blades significantly reduces the force required to cut grass. Sharp blades cleanly slice through the grass, while dull blades tear and require more force.

- Proper Blade Height:Setting the blade height to the appropriate level for the grass type optimizes cutting efficiency. Taller grass requires more force to cut, while shorter grass can be cut with less force.

- Lubrication:Regularly lubricating the mower’s moving parts reduces friction and wear, minimizing the force required to operate it.

- Use of Mulching Kits:Mulching kits allow the mower to finely chop grass clippings and distribute them back into the lawn, eliminating the need for bagging or disposal. This reduces the weight of the mower and requires less force to push.

- Ergonomic Design:Mowers with ergonomic handles and adjustable heights allow users to operate the mower comfortably, reducing fatigue and minimizing the force required.

Strategies for Maximizing Efficiency and Reducing Energy Consumption

In addition to optimizing force exertion, implementing strategies to maximize efficiency and reduce energy consumption further enhances mower performance.

- Mowing in the Right Direction:Mowing in the direction of grass growth reduces resistance and requires less force.

- Overlapping Mowing Paths:Overlapping mowing paths ensures complete grass coverage and reduces the likelihood of missing patches, minimizing the need for multiple passes.

- Avoiding Wet Grass:Mowing wet grass increases resistance and requires more force. It is recommended to wait until the grass is dry before mowing.

- Regular Maintenance:Regular maintenance, including cleaning, sharpening blades, and replacing worn parts, ensures the mower operates efficiently and requires less force to operate.

Examples of Successful Implementation

Numerous manufacturers have successfully implemented techniques and strategies to optimize force exertion in their mower designs. For instance, Honda’s Versamow system incorporates sharp blades, adjustable blade heights, and ergonomic handles, resulting in reduced force requirements and improved efficiency.

Toro’s TimeMaster mowers utilize mulching capabilities, reducing the weight of the mower and minimizing the force required to push. Additionally, their SmartStow feature allows for easy storage, further reducing the physical effort involved in mower maintenance.

Safety Considerations

When operating a mower, it is crucial to prioritize safety to prevent potential hazards and risks. Understanding the force exerted by the mower and its implications is essential for ensuring safe handling and operation.

The following guidelines and recommendations should be strictly adhered to:

Proper Attire and Personal Protective Equipment (PPE)

- Wear appropriate clothing that covers your body and protects you from flying debris, such as long pants, a long-sleeved shirt, and closed-toe shoes.

- Always use hearing protection, such as earplugs or earmuffs, to minimize noise exposure.

- Wear safety glasses or goggles to protect your eyes from flying debris.

Pre-Operation Inspection and Maintenance

- Inspect the mower thoroughly before each use, checking for any loose or damaged parts, such as the blade, belts, and handles.

- Ensure the blade is sharp and balanced to prevent excessive vibration and potential breakage.

- Regularly clean and maintain the mower to prevent buildup of grass clippings and debris that can affect performance and safety.

Safe Operating Practices

- Never operate the mower while under the influence of alcohol or drugs.

- Be aware of your surroundings and keep children and pets away from the operating area.

- Use the mower on a stable, level surface and avoid operating it on slopes or uneven terrain.

- Always hold the mower firmly with both hands and maintain a safe distance from the blade.

- Never reach under the mower while it is running or attempt to clear blockages while the blade is engaged.

- Stop the mower immediately if you encounter any obstacles or experience any unusual vibrations or noises.

FAQ Compilation

What is the primary force exerted by a mower?

The primary force exerted by a mower is the cutting force, which is responsible for severing grass blades.

How does the sharpness of the mower blades affect the force required to cut grass?

Sharper blades require less force to cut grass, as they encounter less resistance from the grass blades.

What are some factors that can increase the force required to mow a lawn?

Factors that can increase the force required to mow a lawn include thick or wet grass, uneven terrain, and dull mower blades.